Manufacturing Types

For outstanding reliability, unparalleled workmanship and high performance that meets any requirement, you have come to the right team. The Group’s timelessly authentic, warm, earthy, natural bricks give character to any build. We ensure that your development will command the character and charm that it deserves when using our products.

Clamp firing is a traditional brick-making method, which is operated from our Freshfield Lane site in Danehill, Sussex. Our large open-sided sheds, each hold approximately 1.5 million bricks that are constructed by hand by an expert team of people in a distinctive pattern that allows them to fire correctly. When the structure is complete the bricks are ignited and allowed to burn naturally. Each clamp takes around 6 weeks to fire and cool.

Our bricks have a timelessly authentic, warm and earthy feel, enabling them to sit in harmony with varied architectural styles. This results in products that are high in demand with architects, self-builders and premium housebuilders. Clamp fired stock bricks have always been a long-lasting, sustainable building material, and you can rely on our bricks to stay beautiful long into the future.

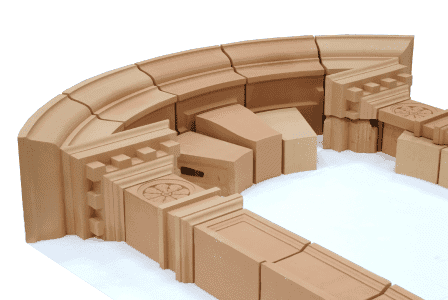

Michelmersh offers the highest quality Hampshire Stock bricks in a unique range of colours and finishes to provide a brick of real character. Producing facing bricks and special shaped bricks from our manufacturing base at Michelmersh near Romsey, we pride ourselves on personal service, which is reflected in our flexible approach and represented in a multitude of award-winning projects.

Our Hampshire Stock range showcase brick blends that have a bold range of deep orange, red and brown hues combined, offering a palette that will make your building facades stand out.

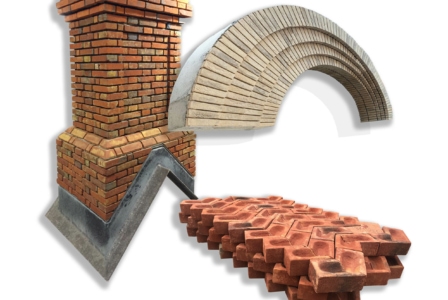

Our renowned products are tailored to our customers’ exact specifications and handcrafted to create a premier finish. We specialise in identifying the most beautiful, suitable products for conservation areas, congruent extensions, prestigious new builds and inspiring architecture in order to enhance our built environment.

Handmade bricks are currently offered in metric, i-line and imperial sizes, in an unrivalled range of colours. We can also develop a truly unique blend to your exact requirements. We match performance with beauty, making Michelmersh the choice of architects.

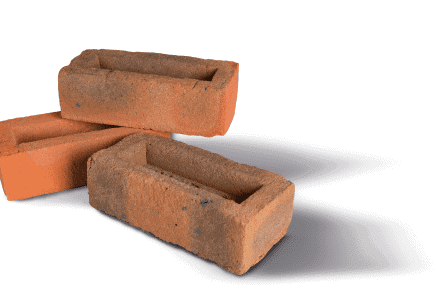

In an extruded process the mixture is pushed through a die (a brick shaped hole) and then cut up into brick pieces using wires, these bricks are called Extruded or Wirecut. The texture on the outside of the brick can be changed by interchanging the dies during the extrusion process.

Michelmersh produces extruded wirecut facing bricks, clay pavers, paving accessories and special shapes from a variety of its brands. Offering our customers the ideal combination of aesthetically appealing clay products. Our extensive range of colours and textures help to build better futures for a wide variety of building typologies including schools, hospitals, offices and apartments from both the public and private sectors, across the UK and overseas.

ESG Strategy

Environmental

Social

Governance

Product Portfolio

Our product portfolio showcases the Michelmersh Group’s extensive product range with a wide cross section of colours and rich textures. For outstanding reliability, unparalleled workmanship and high performance that meets any requirement, you have come to the right manufacturer. Look no further than our timelessly authentic, warm, ‘earthy’, natural bricks to give personality to any build.